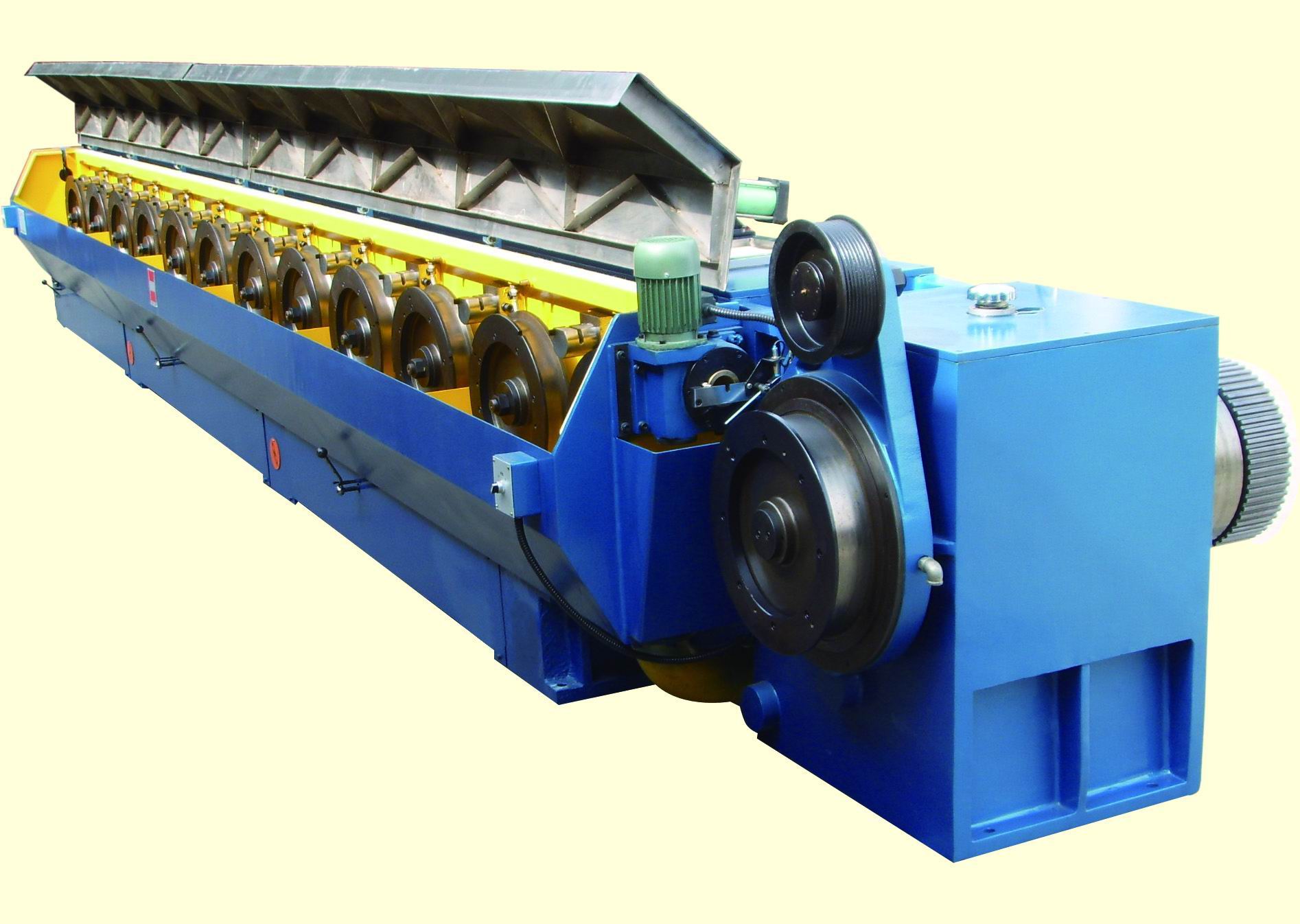

HLC—450/13型连续退火铜大拉 Continuous Annealing Copper Rod Breakdown Machine 本机供电线电缆厂拉制φ1.2~φ3.5的圆铜线,可拉制硬铜线和连续退火软铜线。本机拉线鼓轮采用串列式排列,定速轮和其它12道拉线鼓轮分别由二台直流电机拖动,可进行快速换模,极大地方便了操作。 This machine is made for producing φ1.2~φ3.5 round-shaped copper wire for the wire and cable factory.the drawing capstan are arranged in tandem ,finish capstan and other 12 drawing capstans are seperately dragged by 2 DC machines.This can change the mould fast and make the operation simpler to a large extent. 电控系统采用西门子装置,数字通讯,全线PLC控制,人机界面。 The electrical control is installed with the original Siemens control system,all lines are PLC controlled and human-computer interface 本机收线可配置双盘自动收线装置及成圈下线装置。 The Drawing of this machine can be equipped with dual auto take-up device and coiler take-up device.

一、设备简述 brief introduction to the equipment

本机供电线电缆厂拉制φ1.2~φ3.5的圆铜线,可拉制硬铜线和连续退火软铜线。本机拉线鼓轮采用串列式排列,定速轮和其它12道拉线鼓轮分别由二台直流电机拖动,可进行快速换模,极大地方便了操作。

This machine is made for producing φ1.2~φ3.5 round-shaped copper wire for the wire and cable factory.the drawing capstan are arranged in tandem ,finish capstan and other 12 drawing capstans are seperately dragged by 2 DC machines.This can change the mould fast and make the operation simpler to a large extent.

电控系统采用西门子装置,数字通讯,全线PLC控制,人机界面。

The electrical control is installed with the original Siemens control system,all lines are PLC controlled and human-computer interface

本机收线可配置双盘自动收线装置及成圈下线装置。

The Drawing of this machine can be equipped with dual auto take-up device and coiler take-up device.

二、主要技术参数main technical parameters

1、进线直径inline wire Dia. max. φ8 mm

2、出线直径 outlet wire Dia. max. φ1.2~φ3.5 mm

3、拉线、退火速度 drawing,annealing spped max 25 m/s

4、拉伸道次 number of drafts max 13 道

5、拉线鼓轮直径(等直径)

Dia. of drawing capstan (equal Dia.) φ450 mm

6、最大模具尺寸 Max. mould size φ43×35 mm

7、成圈收线容量 coiler take-up volume 2 t

收线范围 take-up range φ3.5~φ1.6 mm

收线速度 take-up speed max. 15 m/s

8、双盘收线盘规格 type of dual take-up PND630 PND500

9、最大退火电流 Max.annealing curent 6000 A

10、最大退火电压 Max.annealing voltage 55 V

11、拉线主电机 drawing host

型号 type Z4-315-12

功率 power 280 kw

12、定速轮电机 electric machine of finish capstan

型号 type Z4-200-21

功率 power 75 kw

13、双盘收线电机 dual take-up motor

型号 type Z4-160-31

功率 power 30x2 kw

14、主机润滑油泵 oil pump of host lubrication

CBZ-50 50L/min 3 kw

15、储线装置储线长度

Wire length in accumulator max. 约5.2 m

16、储线轮最大行程 max. stroke of accumulator ring 840 mm

17、使用压缩空气压力(气源用户自理)pressure of required compressed air

(the air source are resolved by the buyer) 0.4~0.6 Mpa

18、电蒸汽炉加热功率 lectric vapour heating power 9 kw

三、设备组成equipment comprises:

1、放线架 pay-off stand 1套

2、拉线机主机(包括主电机、定速轮电机) 1套

host of wire drawing (including electric host and finish capstan electric host)

3、连续退火装置 1套

Continuous annealing device

4、储线装置 accumulator 1套

5、双盘收线装置 dual take-up device 1套

6、成圈收线装置 coiler take-up deivce 1套

7、拉线主机润滑装置 drawing host lubrication device 1套

8、轧头穿模机 wire pointer and stripper 1套

9、电气控制柜 electric control cabinet 1套

10、电蒸炉 electric vapour furnace 1套

四、设备技术特点characteristics of equipment

1、拉线牙箱整体铸造,与分体拼结结构相比,刚性大大提高,不会变形,密封性好,不会产生漏水、漏油等现象。

Xx is founded in whole*,compare with being founded seperately,the xx has been enhanced and it’s not easily transfigurable,it’s leak-free from water, oil etc.

2、拉线机采用高性能斜齿轮传动,全方位加工。高速档齿轮齿面淬火磨齿。拉线鼓轮采用中碳钢基体,表面喷涂碳化钨。

Wire stretcher is equipped with high-qualified inclining gear transmission,omnidirectionally processed. High-gear is quenched and the drawing capstan is made of medium carbon steel matrix with tungsten carbide sprayed on the surface

3、采用半浸没式润滑冷却方式,确保线材和拉线模有效的冷却和润滑

Cooling adoption of semi-dipping lubrication ensures the wire and the mould being cooled and lubricatd efficiently.

4、退火装置设计为倾斜式,降低了高度,操作方便。专门设计的风道使退火轮后部变得十分简洁,方便了日常维护保养。

The annealing device is inclination type and it’s easy to operate because of the lowered height. The design of airway makes the back of fire-ring more simple and convenient for maintenace.

5、双盘收线设计先进可靠,有关传动部分均进行动平衡校正,采用气动系统及电气通讯方式控制换盘,稳定性好,捕捉成功率高。由于采用气动控制,工作场地整洁干净,解决了选用液压系统可能产生的漏油现象。

Dual take-up design is advanced and transmission parts are dynamic balancing emendated,using a air-started system and electric communication to control the changer is good for stablity and a high success rate of capture.because of the air-starting control,the workplace can be tidy and clean ,this solved the oil-leaking problem of liquid pressure system.

6、拉线主机、定速轮、成圈收线及双盘收线电机均采用原装西门子控制器,全线PLC控制,采用进口人机界面,能方便地发出操作指令,察看整机运行状况,调整工艺参数,并具有故障诊断功能。

Drawing host, finish capstan,coiling take-up and dual drawing motor are all imported from Siemens,all line PLC controlled with a human-computer interface.This makes the command and adjust of running situationa and parameters easy,and it is error-detection possible.

7、定速轮内设有水冷或风冷机构,可有效降低拉线时定速轮温度。

Finish capstan has a water-cooling or wind-cooling device,can cool of the capstan while drawing.